Sure Evacuation with RFID

How using RFID can help prevent fatal accidents during evacuations

- By Karolina Kozlowska, PhD.

- July 21, 2017

The greatest nightmare of an evacuation coordinator is to finish evacuation before all employees reach the assembly point. Such disaster can be prevented with RFID UHF technology because it gives complete knowledge on location of every person that needs to be evacuated.

The aim of every evacuation is unchangeable: to get all employees out from an endangered area as quickly as possible. During the evacuation process, its coordinator should be able to control the location of every single person in real time, and to be able to determine who has already left the endangered building, who has reached which assembly point (there may be a number of them and they are run by separate coordinators), and who is still in building.

However, current methods do not guarantee the optimal course of evacuation. Therefore, they do not guarantee employees the full safety in a situation of sudden danger. RFID UHF technology may be used for creating evacuation systems.

It Starts Before a Siren

Evacuations should commence before any real danger occurs. After all, the key information is how many employees and which one of them (by name) should be lead to an assembly point. Every employee should have an assembly point that has been assigned to them. And, what’s natural, people’s location changes during worktime. People move between buildings, leave one and enter another. When sirens rip through the air, the coordinator should theoretically know who he should funnel to a safe place. But if he lacks a list of employees and their locations, he doesn’t know who to provide safety to. Therefore, precise location of staff should be constantly monitored.

Premium Knowledge

In many factories, there are still systems in use in which a coordinator is the only person who can verify people reaching assembly point. He counts employees, reads their names aloud or circulates among them, ticking the names off as he goes down the list.

It is easy to come to the conclusion that such a method is rather imprecise. And its imprecision generates risk that can generate tragic consequences. One man may be omitted or someone’s name could be ticked accidentally. And when evacuation is finished, somebody can be simply left behind.

Why RFID?

Facing all these challenges and difficulties and, most importantly, bearing in mind the safety of staff, it is recommended to look closer at RFID UHF technology. What conveniences does it bring for an evacuation coordinator? How much does it increase chances for successful evacuation? How does evacuation change when RFID UHF is used?

Some words of introductions are needed to explain why this technology should be considered at all. What makes it remarkable are its features. It can automatically detect even 300 markers (RFID UHF tags) within 1 second. Markers can be read from 8 meters. Read precision is 99.7 percent. And, finally, marker is correctly identified even through obstacles (e.g. through clothes or cardboards), without visual contact between RFID UHF reader and tag.

These features make RFID UHF the perfect tool for all identification, scanning and identifying processes. It has been proved by many RFID UHF implementations in such areas as retail, logistics or aviation.

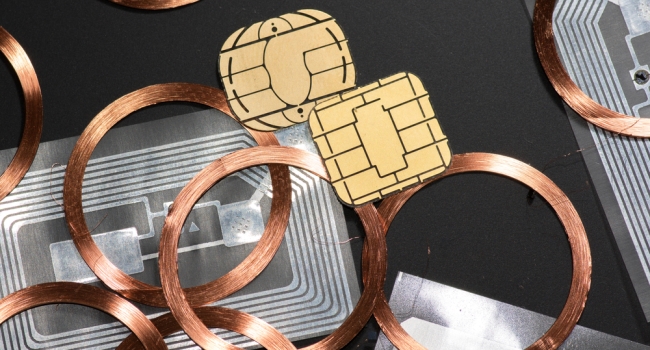

RFID UHF technology became popular due to its tags. Compared to other markers – especially beacons – they stand out with great variety of sizes and shapes. No battery is required for RFID UHF tags to work, making them ready to mark various objects in countless situations.

Such wide range of applications makes RFID perfectly suitable for evacuation systems. This technology gives coordinator the full knowledge and increases the safety level of evacuated people.

RFID Makes Difference

An evacuation system based on RFID consists of readers, antennas and RFID tags. These tags – in a form of light and convenient lanyard – contain information about every employee. Data is written on a lanyard and is read by antennas and then transmitted to readers. From there it goes to computers, tablets or smartphones used by managers and evacuation coordinators.

In this way employees are being monitored in real time. When a danger occurs, coordinators immediately know who must be evacuated. Staff knows perfectly well what to do. Their only duty is simply to go to assigned assembly point. When people exit, they are automatically and collectively identified due to the lanyard-tags they carry.

Simultaneously, when they leave, a coordinator is notified of who is leaving building. The number of people does not matter: RFID UHF technology perfectly handles the simultaneous identification of many employees. The before mentioned precision (99.7 percent) the risk of omitting any man or incorrectly scanning tag is practically none.

The same mechanism works at assembly points. Installed antennas correctly recognize incoming employees (single and groups), sending information to reader and then to coordinator. By looking at his computer or any mobile device he can easily see who is in a safe place. He can check to see who is still in an endangered area.

Straight Ahead to Safety

It is impossible to overlook the technology advantages of RFID UHF, especially in terms of increasing evacuation safety. Thanks to its scalability and simple software integration with applications used in factories, it can be used in every company, regardless of its area or number of personnel. By using RFID UHF for evacuations, the risk of fatal accidents is significantly lowered.